Saica 2025: Contributing to sustainable development goals

We join the United Nations Sustainable Development Goals (SDGs) and align our Saica 2025 Strategic Plan and our future commitments with them. We believe that a sustainable future is possible.

Circular Economy: the core of our business

Integrating sustainability into our strategy has enabled us to expand our business model by adopting the circular economy as the driving force to achieve a more responsible production model.

Corrugated paper and cardboard cycle

We recover paper and cardboard waste and reintroduce it over and over again into the production cycle. Paper and cardboard waste is recycled in our factories to become 100% recycled paper reels that will give rise to new packaging in the corrugated cardboard plants. In this way we ensure that waste is converted into new products, thus avoiding it being sent to landfill.

Low Density Polyethylene Cycle

We recycle low-density polyethylene (LDPE) waste, transforming it into pellets that are later used in the packaging, construction, agriculture or automotive industries in the form of recyclable film, thus reducing the virgin pellets consumed by our clients.

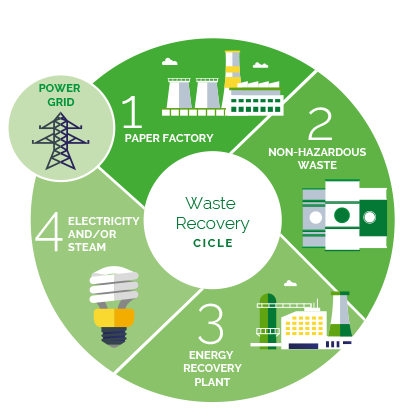

Waste energy recovery

We give a second life to the non-hazardous waste generated in the paper manufacturing process. This waste, together with that from external origin, mainly biomass, is used as fuel to generate the thermal energy necessary for the production process or to produce electricity that is exported to the grid, replacing natural gas.

Sustainability report

Our commitment to the circular economy is expressed through the every two years publication of the Sustainability Report as the maximum exponent of our spirit and our responsible management.

- 2017

- 2019

- 2021

- 2022-2023

Initiatives

We work with various external partners to ensure transparency and sustainable development.

SEDEX

The Supplier Ethical Data Exchange is a non-profit organisation that disseminates ethical and responsible business practices in the development of global supply chains. Saica Pack is registered on this platform so that its stakeholders have a reference of the implementation and compliance with sustainability standards in terms of occupational safety, environment and business ethics

ECOVADIS

Provides sustainability ratings to suppliers to ensure supply chain development while maintaining levels of quality and integrity.

CDP

Carbon Disclosure Project requests information on the management of risks and opportunities that climate change and water represent. Several multinationals and their suppliers already rely on the CDP Supply Chain Programme to achieve sustainable supply chain management.

Certificates

Learn all about our plants' certificates

Saica Group Policies

Learn about all the applicable policies in all areas of the Saica Group

Cookies notice

This website uses its own and third party cookies for technical and analytical purposes.

For more information, you can visit our Cookies Policy. If you click the "Accept all" button, you are consenting to all cookies. Likewise, you can configure or reject them in our Cookie Settings Center.