Reckitt Visits Saica PM11 for a Day of Insight, Innovation and Collaboration

Manchester, 11 Dec 2025

Saica Group recently welcomed its customer Reckitt to our PM11 site in Manchester for a full day dedicated to technical learning, collaboration and strengthening the partnership between both organisations. Reckitt manufacture some of the world's best-loved and trusted Hygiene and Health brands. The visit formed part of our shared ambition to improve packaging performance while driving progress in sustainability and innovation.

From the outset, the day offered a valuable opportunity to explore how Saica’s operations, expertise and technology come together — and how our distinctive end-to-end approach can support customers like Reckitt in achieving their environmental and commercial goals.

A Closer Look at Saica’s End-to-End Approach

Throughout the sessions, the Reckitt team were introduced to Saica Group’s unique end-to-end model, which spans the entire packaging lifecycle.

This end-to-end view is central to how Saica creates value. By analysing the whole chain, we are able to identify efficiencies, optimise raw material usage, and help customers reduce their environmental impact without compromising product performance. The discussions highlighted the growing importance of full-chain insight as brands look to balance sustainability requirements with cost and operational demands.

Sharing Knowledge and Exploring Innovation

Technical experts from both Saica Paper and Saica Pack contributed to a series of focused sessions covering:

• The paper-making process behind PM11

• Material performance and fibre optimisation

• Structural and design considerations in corrugated packaging

• Emerging opportunities in sustainable packaging development

• How innovation and collaboration can accelerate improvement across categories

These conversations sparked a range of ideas, particularly around the role of design efficiency and responsible material selection in future packaging strategies.

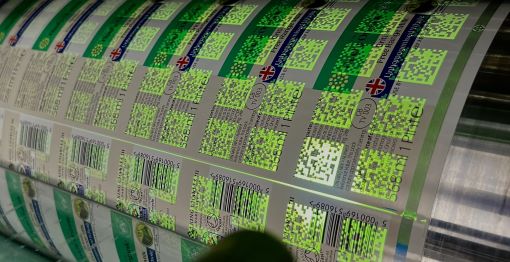

Inside PM11: A First-Hand Look at Modern Manufacturing

A tour of the PM11 facility brought the learning to life. The Reckitt team were able to see the scale, precision and technological capability that sit behind Saica’s paper production. From advanced quality control systems to energy-efficient manufacturing, the visit provided a clear view of how sustainability is embedded into operations at every level.

The tour also offered a deeper understanding of the circularity at the heart of Saica’s business model, demonstrating how recovered fibre is transformed into high-performance paper suitable for a wide range of packaging applications.

Building a Stronger Partnership for the Future

As the day concluded, it was clear that the visit had reinforced the strong working relationship between Saica and Reckitt. The open exchange of ideas, combined with the chance to immerse in Saica’s technical processes, created a foundation for further collaboration in areas such as product development, material innovation and shared sustainability goals.

Saica Group extends its thanks to the Reckitt team for their engagement and enthusiasm. We look forward to continuing to work closely together and to exploring the opportunities that lie ahead.