Polytag, Saica Flex, and Paragon Inks Announce Strategic Partnership to Transform Waste Journey Traceability

London, 16 Feb 2026

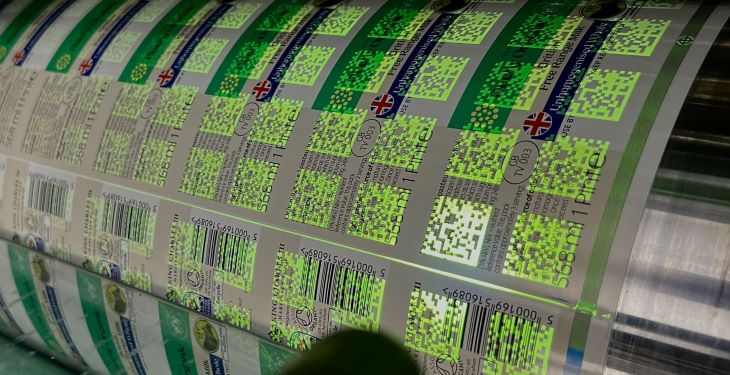

Polytag, Saica Flex, and Paragon have announced a strategic partnership to deliver innovative UV-tagged packaging labels, designed to provide brands with real-time, actionable environmental data. This collaboration combines Polytag’s cutting-edge detection technology and expertise, Saica Flex’s high-quality packaging production, and Paragon Inks specialist UV inks.

The collaboration is already having tangible impact, with labels produced for Waitrose milk cartons now in-market and actively generating verified, reliable recycling data.

A product built for scalability and seamless integration

The labels carry invisible UV tags, printed with Paragon’s inks products. Once they enter the recycling stream, Polytag’s detection systems scan the labels and capture detailed, item-level data. Using this data, recyclers can track in real time which products enter recycling, measure recovery rates, and demonstrate compliance with regulations such as Extended Producer Responsibility (EPR), facilitating the sharing of this information with brands.

Crucially, the solution integrates seamlessly and cost-effectively into existing packaging and printing workflows. Saica Flex’s close collaboration with Waitrose, combined with its experience in this specific packaging, enabled rapid and reliable deployment without disrupting established supply chains.

Francisco Barrera, Sales & Marketing Director at Saica Flex, explained: "We knew from the start that adoption would depend on keeping things simple. Brands need solutions that fit naturally into their operations and current production environments. This product works across the entire packaging lifecycle, from printing through recycling with minimal disruption. It gives brands meaningful insight, while remaining practical and viable even for high-volume products like milk cartons."

Alice Rackley, CEO of Polytag added: "And because it’s built on GS1 global open standards, the UV tag solution is ready to scale across multiple sectors and applications, allowing brands and recyclers to participate fully in building a transparent circular economy."

Rigorous testing for recyclability and safety

The UV inks underwent extensive development and testing to ensure full compatibility with standard waste management processes. The labels can be chipped down or separated through flotation, and any residual ink behaves in line with other approved UV products, ensuring no contamination of recovered materials.

Barbara Paterson, Technical Director at Paragon Inks, said: "Creating the UV inks was a technical challenge. They needed to remain detectable by Polytag readers across a wide range of colours, substrates, and packaging formats, even after packaging has been crushed or otherwise processed. At the same time, the inks had to meet strict food-safety and environmental requirements. Two years of development, testing, and iterative validation went into delivering a solution that is reliable, safe, and fully compatible with existing waste management operations."

Real-world impact

The partnership’s success is already evident. Labels printed by Saica Flex with Paragon Ink’s products are now in use on Waitrose milk cartons and actively being detected by Polytag systems in recycling facilities; Giving the brand, new levels of transparency and insight into packaging performance, backed by live verifiable proof of recycling.

"Seeing the labels generate real data in a live waste stream validates all the work that went into development," said Martin Fowler, Global Sales Director at Paragon Inks. "It proves the system works as intended, and this is just the beginning - the potential for other products and sectors is enormous."

Shared values driving innovation

Beyond technology, the partnership thrives on shared values: sustainability, circular economy principles, and a drive to create meaningful impact.

Alice Rackley said: "What makes this partnership work so well is that all three companies are aligned in purpose. From day one, the focus has been on delivering practical, scalable solutions that make a difference for brands and the environment."

A collaboration enabling a circular future

With regulatory pressure mounting and consumer expectations evolving, the collaboration will enable brands to understand their packaging’s journey and take the lead in sustainability. The UV label solution is ready to scale across multiple packaging formats, from beverages and dairy to a wide range of consumer goods, delivering actionable, verifiable environmental data and enabling measurable progress in environmental performance.

Francisco Barrera concluded: "This partnership is about more than labels. What we’re creating is exciting: packaging that tells a story about sustainability and waste management . Through this collaboration, we’re giving brands insight and control over their environmental performance, making recycling measurable, actionable, and scalable. It’s a real game-changer for the industry, and we encourage more brands to embrace this solution to make a tangible, positive impact on the circular economy."

About the Saica Group

The Saica Group offers sustainable paper solutions for the manufacturing of corrugated cardboard and packaging, promoting circularity in waste management. With more than 12,000 employees and a presence in Spain, France, Italy, Portugal, the United Kingdom, Ireland, Turkey, Luxembourg, the Netherlands, Poland and the United States, the Saica Group has four business divisions: the manufacturing recycled paper for corrugated board (Saica Paper), waste management and environmental services (Saica Natur), the production of corrugated board packaging (Saica Pack) and flexible packaging (Saica Flex). The group's turnover is 3,962 million euros (consolidated sales on 31 December 2025).

About Paragon Inks

Paragon Inks specialises in UV and water-based inks and coatings for web-printing applications, delivering high-quality systems to the global packaging and labelling market. Built on integrity, collaboration and performance, we work closely with customers, distributors and suppliers to meet the demands of modern print. With over 30 years of UK manufacturing expertise, Paragon Inks supplies converters in more than 67 countries and is recognised for consistent quality, technical service and customer commitment. Known for innovation, traceability and partnership, we create lasting value by uniting expertise, service and supply.

Paragon Inks is a proud member of the ALDUS™ Group, a global leader in packaging and labelling technology. Group membership enhances our capabilities through shared resources, technical expertise and supply chain insight, while retaining our agility and customer-first approach. The Aldus Group brings together specialist businesses across label and packaging technologies, print machinery and consumables, and foils, coatings and transfer products, with operations across Australasia, Europe and the Americas—delivering global innovation with local support.

About Polytag

Polytag’s invisible UV tags can be read at enabled Material Recovery Facilities (MRFs) using Polytag Detection Units, delivering real-time, item-level packaging recycling data. Polytag currently operates a network of 14 Detection Units installed across UK recycling centres, providing brands with unprecedented visibility of what is actually recycled.

In April 2026, the world’s first industrial-scale detect and sort unit will be installed in a UK recycling centre, marking a major step forward in advanced sortation technology. This capability will enable more accurate separation of tagged packaging, unlocking improved access to high-quality post-consumer recycled (PCR) material and helping to close the value gap in plastic recycling.

Working with Polytag brings brands closer to recovering and recycling their own packaging at scale, supporting compliance with emerging packaging regulations while accelerating progress towards a truly circular plastics economy.

Polytag’s QR codes integrate seamlessly with existing packaging and supply chain systems, requiring no additional materials or disruptive changes. The company has a proven track record of successful deployments with printing hardware solution providers and label converters, using both digital and in-line plate printing processes.