Facilities

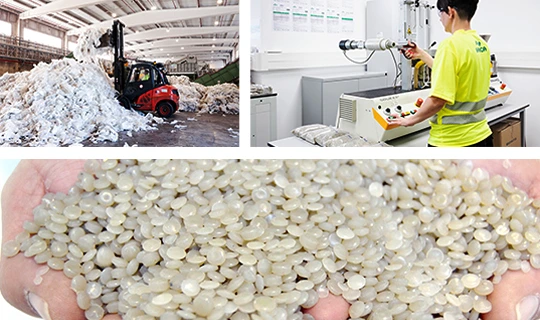

The plant is dedicated to the recovery, sorting, treatment, and transformation of low-density polyethylene (LDPE and LLDPE) to produce granules reintroduced into the production cycle for manufacturing new plastic products. We employ the best available technology on the market, making us a global reference in product quality and technical, energy, and environmental efficiency.

It operates as a continuous process (sorting, crushing, washing, drying, and extrusion) with various control systems to offer our customers high-performance granules as a substitute for virgin granules without altering the mechanical characteristics of the final product.

Product

The product manufactured at our facilities is a homogeneous granule, with a high degree of processability, transparency, and no odors, capable of increasing the substitution of virgin granules without altering the mechanical characteristics of the final product.

We have various control systems that allow us to guarantee the quality and traceability of the supplied granules.

We offer our customers the possibility of joint product development, technical assistance at their facilities, and the provision of a technical data sheet.

Cookies notice

This website uses its own and third party cookies for technical and analytical purposes.

For more information, you can visit our Cookies Policy. If you click the "Accept all" button, you are consenting to all cookies. Likewise, you can configure or reject them in our Cookie Settings Center.