Advanced simulation for corrugated cardboard packaging design and optimisation

Zaragoza; Spain, 21 Dec 2017

The use of simulation tools to analyse corrugated cardboard comes with two significant challenges. On the one hand, paper is one of the most complex materials as concerns the mechanics and requires the development of specific models for its simulation if it is to be done with the proper precision since added to its straight, non-linear shape are traction and pressure behaviour differences as well as the complex viscoelasticity and the influence of environmental conditions on its behaviour, which means there are no commercial tools that can be directly applied without a tedious preliminary adaptation and personalisation process. On the other hand, the very structure of the waves makes it difficult to obtain computationally efficient models which can be generated in short periods of time and which can also be used for optimisation processes with many different simultations occuring simultaneously.

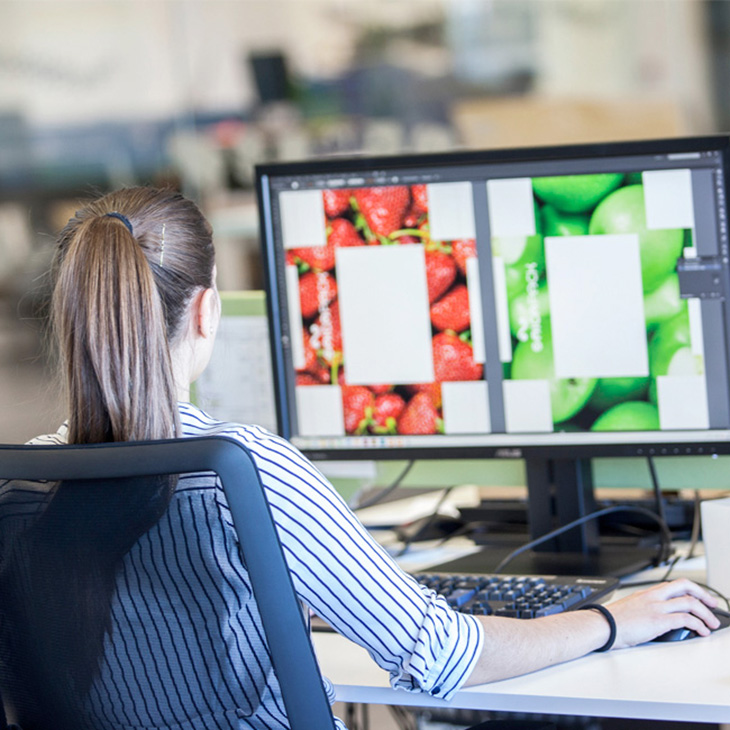

Saica R+D already faced the two challenges in the first decade of the 21st century and launched a collaboration programme with ITAINNOVA (www.itainnova.es) aimed at creating its own simulation method for paper and corrugated cardboard based on FEM (finite element method) and adapted to the box design and optimisation. The process of developing the simulation tools available to Saica R+D today for advanced corrugated cardboard packaging analysis has required programming internal behavioural models for paper based on complete paper and cardboard testing plans which were used to actually created the models and validate them before final implementation. Nowadays and as a continuation of its collaboration with ITAINNOVA, SAICA R+D has the capacity to conduct advanced analysis by simulating the resistance behaviour of different types of corrugated cardboard boxes from the traditional B1 boxes to a long list of agricultural trays as well as other types of customised designs for which simulation can analyse details such as the handle positions or location of pre-cut lines for easier box opening. These capabilities are used to support the NDCs in the development of innovative products for fast computerised evaluation of the different design solutions and variations in the cardboard compositions in order to guarantee the final designs satisfactorily comply with the established resistance requirements.Moreover, the advanced paper and cardboard simulation models are also used for other Saica R+D projects to analyse how certain details of the cardboard manufacturing process influence the mechanical behaviour of the end packaging.